Purchasing a Raman spectrometer?

If you are in the market to purchase a new (or upgrade an existing) Raman analyzer for your process or lab, you may already realize there are a variety of available options. As an analytical instrument, the Raman analyzer identifies a chemical species and/or structure or the concentration of substances. Choosing the right Raman analyzer is about selecting between a number of trade-offs. Parameters to consider include speed of measurement, accuracy and precision, superior software interfaces, calibration stability, sampling options, and instrument robustness.

To help deal with the challenges of choosing a new Raman analyzer, our latest blog is intended to be used as a practical guide to allow PAT scientists, process development chemists, or process control engineers who are considering adopting Raman spectroscopy as a process analytic technology.

Features of a reliable instrument

Speed of measurement

One of the major criteria in selecting a Raman analyzer is speed of measurement. A powerful laser (≈500 mW) combined with a high-throughput spectrometer delivers the fastest spectral acquisition time by provided exposures in milliseconds. This leads to lower limits of detection and provides actionable information in real time for your process. In the specialty chemical and pharmaceutical space, finer measurement resolution does make a significant difference where measurements are made in parts per million. For example, one of our customers needed to quantify their reactant at a concentration of 400 ppm, but the current state-of-the-art equipment could not measure to that resolution fast enough. The difference for the customer in being able to measure more precisely is vast. In the biopharmaceutical industry, fast, precise measurement can assist companies during the purification process and enable them to achieve reliable real-time results.

Accuracy and Precision

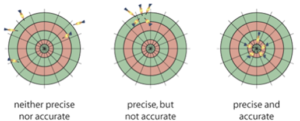

Measurement error is the difference between the measured value and the ‘true value’ of the thing being measured. Two factors in a measurement are:

- Accuracy – How close is the measurement to an accepted reference?

- Precision – How close are repeated measurements to each other?

Here, the ultimate objective is to reduce the risk of measurement error by checking the measurement a second or third time:

Tornado’s analyzer takes many fast measurements to dramatically improve the precision. Improved precision enables the resolution of the measurement to be as low as 30 parts in 1 million (0.003%). This allows for improved quality, better process efficiency, and a deeper understanding of the incoming materials to enable superior control.

The term precision is used to express the random contribution of measurement uncertainty. Like many measurement instruments, the precision of the Raman analyzer must not be overlooked. Tornado’s HTVS™ technology allows a spectrometer to collect 10 times more photons than the previous state-of-the-art equipment, which in turn improves the precision of the measurement of chemicals in a mixture.

Software

There has been enormous progress in the analytical instrumentation space as improvements are made to sensitivity, limits of detection, and accessibility. In order to harness a high degree of automation, it is critical to invest in powerful software. Without solid command & control software, end-users will not be able to capture, store, process, and report on their Raman spectra and resulting in real-time measurements. Smart software has proven to take our customers to the next level and therefore it’s critical we have a powerful solution that can help filter out what you don’t need and isolate what is relevant/important. With both Modbus and OPC-UA connectivity, Tornado’s Raman analyzers can seamlessly interface with process control and DCS systems.

Another key part of the puzzle is multivariate analysis (MVA) and chemometrics, the art/science of creating a mathematical algorithm to extract important chemical information from the raw spectroscopic data. At Tornado, our Raman analyzer control software outputs data in a standard format that can be read by any of the common chemometric software packages. At the core of our analyzer is Tornado’s HTVS™ technology which creates a stronger photonic signal so that the digital parts of the system (the CCD detector and the MVA algorithms) can work more effectively. With Tornado’s spectrometers and technology, users can rest assured that they will get data with a higher degree of accuracy and confidence to support their findings and conclusions.

Calibration

There are two types of calibrations for Raman analyzers: light source calibration and path-length calibration. The luminosity of the light source decreases with use and must be calibrated once every 1 to 2 years. This can now be done by simply consulting the parameters provided by the manufacturer and calibrating the analyzer yourself without having to send it to a process engineer.

If used in a continuous system, calibration is, of course, the major consideration in making sure the Raman system remains reliable. Frequent calibrations often interrupt experiments or processes, so a stable system is a must. In order to minimize the issues encountered during the usage of the analyzer, Tornado has built the HyperFlux™ PRO Plus for maximum stability which does not require frequent calibrations.

Sampling options – probes and cells

When working with a variety of sampling options, it is key to work with a manufacturer who understands your process monitoring application. Immersion probes, stand-off probes, non-contact probes, and a variety of flow cells will better support the sampling and measurement reproducibility for liquids, solids, slurries, powders, and heterogeneous mixtures. By doing so, they can collect high-quality data on either flowing or stationary samples and allow users to optimize accuracy, quality, and yield over a wide range of processes. For users looking to generate high signal-to-noise ratio spectra at short exposure times, Tornado recommends the Hudson 785 non-contact Raman probe.

Robustness

If you need a robust analyzer you should consider going for:

- High-Throughput spectrometers

- Complete software suite from lab to manufacturing

- Sampling accessories optically matched to the spectrometer

Conclusion

Without a doubt, Raman spectroscopy continues to be a cutting-edge analytical technique that will likely continue to be applied in even more industries and markets in the future. Understanding the influence of what is required is critical to evaluate the overall performance of different analyzers. As with any purchase, be sure to do your homework and understand your needs before purchasing.

If you would like to discuss your application and are considering adopting Raman spectroscopy as a process analytic technology, please contact us at [email protected]