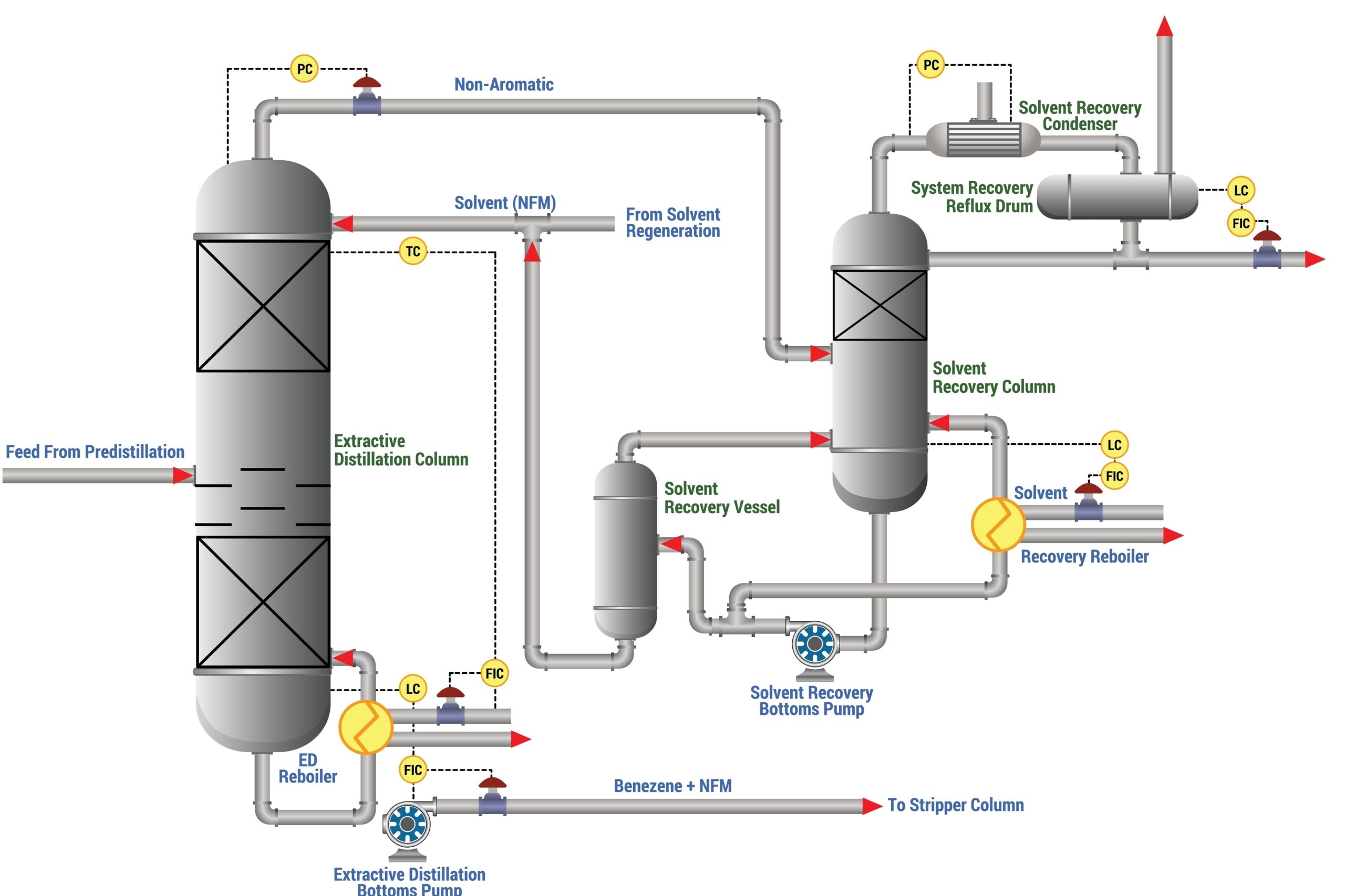

Raman Spectroscopy enables real-time automatic chemical measurements and is critical for the specialty chemical industry. A fast, precise, and selective Raman measurement keeping up with the flow to improve quality/yield can produce a detailed analysis of complex mixtures.

Tornado’s HTVS™ technology addresses the issues of speed and sensitivity. Because we allow a higher photon flux with the HTVS™ technology, we can collect data to achieve a required signal-to-noise ratio faster than a conventional spectrometer. This allows faster decisions to be made in process to circumvent excursions, therefore eliminating, or at least minimizing, the disruptions that can occur because of those excursions.

Sensitivity is the major concern for most users and the high photon flux that we facilitate ultimately allows for better signal-to-noise than a conventional spectrometer in a given measurement time. This allows for lower detection limits and, thus, more precise control.