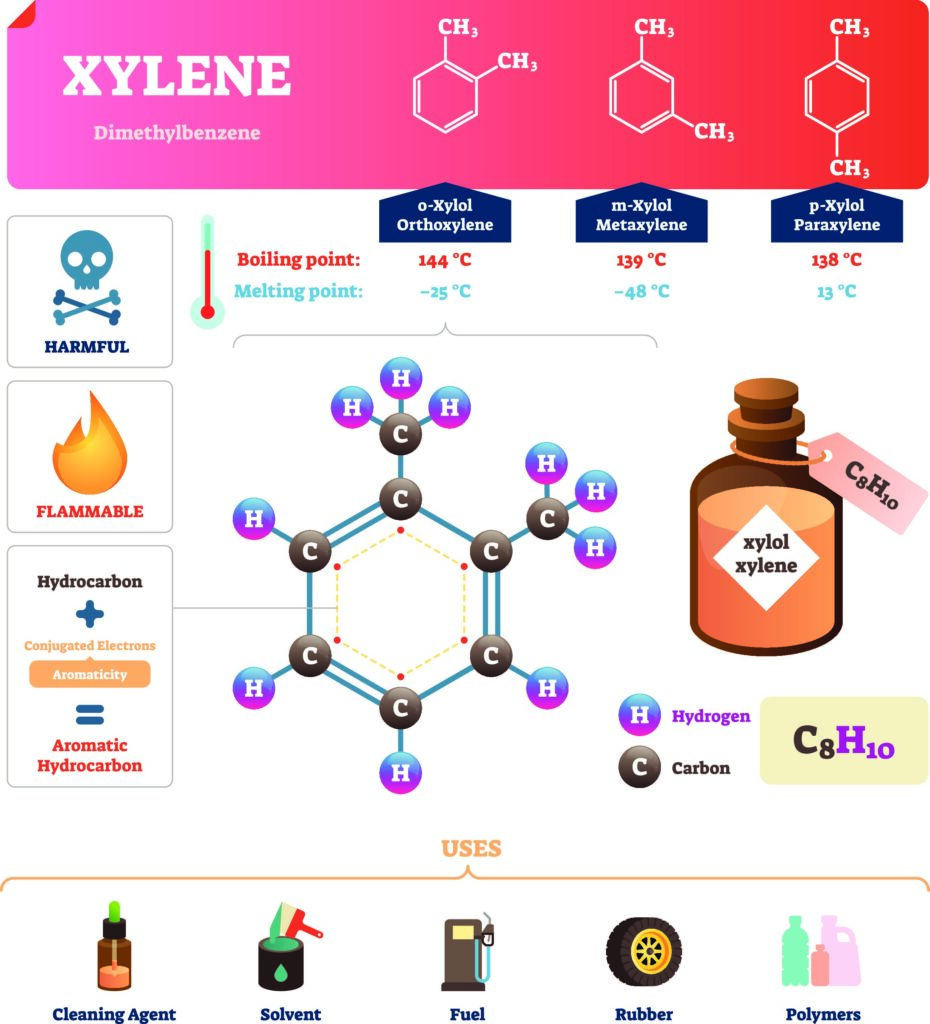

Understanding the properties of plastics and polymers is a critical step in optimizing their performance. Raman spectroscopy is widely used in the characterization of polymers and plastics and helps in determining their composition, which can include copolymers and blends, additives, antioxidants, and crystallinity.

Unrivaled measurement speed for your manufacturing process

The non-destructive nature of Raman measurements along with the molecular specificity of the spectra make it an optimal technique to monitor manufacturing processes in real-time.

Tornado’s Raman systems provide you with the speed and sensitivity to investigate all polymer types.

Applications & Advantages of Raman Analysis

- Polymerization reactions

- Kinetics

- Process optimization

- Side products

- Additives

- Degradation

- Residual monomer

- End point determination

- Recognize excursions quickly

Polymer Curing

- Assure adequate curing has occurred

- Ensure product performance

- Online or at-line or lab

- Non-contact measurements

- Fast curing processes

Extrusion

- Monitor melt in-line

- Melt constitution

- Additives

- Recycling

- Degradation

- Recognize excursions quickly

Plastics & Polymers Related Blogs

“The Tornado HyperFlux PROPlus has gathered thousands of reproducible spectra since we acquired it in mid-2019 without requiring a single repair.”

What our

clients say

– Angela Spangenberg, Senior Research Scientist, DisperSol Technologies